Testing equipment and technology

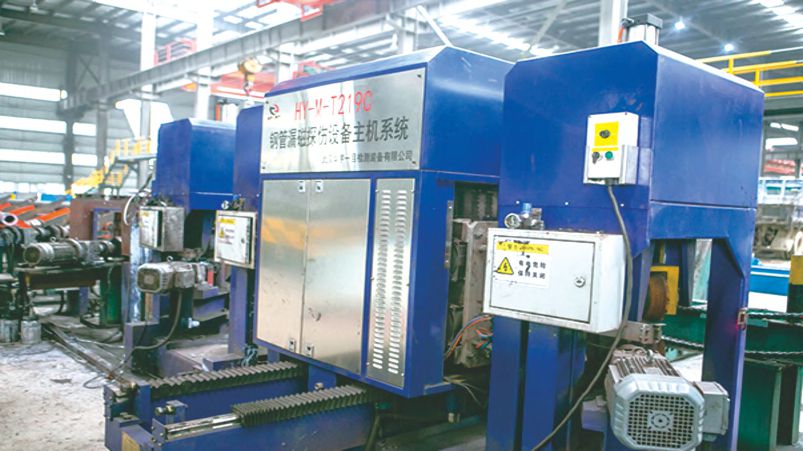

Magnetic leakage detection system for steel pipes

Dayang Steel Pipe is equipped with steel pipe leakage magnetic flaw detection system. This system adopts the scanning method of pipe spiral advancement, segmented longitudinal and transverse magnetization, signal acquisition and channel processing of steel pipe, which can subdivide the defective signals and objectively respond to the defective conditions. The longitudinal and transverse probe adopts a strip-shaped probe shoe, which has a compact structure to ensure the reliability of the product and provide effective quality control for the petroleum equipment series products.

Ultrasonic flaw detection system for steel pipes

Dayang Steel Pipe is equipped with an ultrasonic flaw detection system for steel pipes, which is suitable for accurate flaw detection after the production of workpieces or random inspection of finished products. The automated flaw detection process includes automatic loading, roller conveyor transfer, ultrasonic flaw detector inspection and discharging system, and the inspection result triggers automatic alarm, marking and sorting.

Tube Hydraulic Press Flaw Detection System

The company is equipped with steel pipe hydraulic press flaw detection system, which utilizes oil-water balance control to conduct hydrostatic pressure resistance test on steel pipe, applicable to petroleum pipe and pipeline pipe with pressure-bearing requirements. The outer diameter range is 60~457mm.

Physical and Chemical Testing Center

Our physical and chemical inspection center laboratory is a key laboratory in Shandong Province, with a building area of 2,000 square meters, more than 20 professional and technical personnel, equipped with a series of advanced testing equipment, including metallographic specimen cutter, universal testing machine, spectrometer, etc., which provides strong support for the performance analysis and technical appraisal of the steel pipe. The long-term industry-university-research cooperation with Taiyuan University of Science and Technology further promotes the continuous improvement of product quality.

Shandong Dayang Steel Pipe Group has always been based on strict quality inspection standards to ensure that each batch of products meets the strict quality requirements. We are committed to providing customers with high quality steel pipe products and setting up a quality benchmark for the industry.

List of test center equipment

spectrograph

spectrograph Impact Tester

Impact Tester Zeiss metallographic microscope

Zeiss metallographic microscope Metallographic specimen cutting machine

Metallographic specimen cutting machine Metallographic specimen grinding and polishing machine

Metallographic specimen grinding and polishing machine Microcomputer control electro-hydraulic servo universal testing machine

Microcomputer control electro-hydraulic servo universal testing machine Microcomputer control impact tester

Microcomputer control impact tester Multi-point Tensile Specimen Moment Scale

Multi-point Tensile Specimen Moment Scale spectral milling machine

spectral milling machine CSL-Y Impact specimen notch double knife hydraulic broaching machine

CSL-Y Impact specimen notch double knife hydraulic broaching machine Digital Rockwell hardness tester

Digital Rockwell hardness tester Digital Vickers hardness tester

Digital Vickers hardness tester